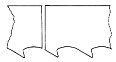

Premature

Tooth Wear

|

Feed pressure too light; Increase pressure.

Insufficient or improper coolant at blade entry.

Incorrect tooth selection.

Improper break-in of new band.

Hard spot in material.

|

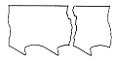

Wear on Back

|

Guide arms too far apart.

Blade rubbing on wheel flanges.

Insufficient blade tension.

Excessive feed pressure.

|

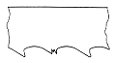

Straight Break

|

Blade tension too high; Reduce.

Excessive feed pressure.

Teeth contacts work before saw starts.

Worn or chipped backup guide.

Blade rubbing on wheel flanges.

Side guides adjusted too tight.

Teeth too coarse for work piece.

|

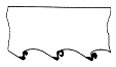

Irregular Break

|

Metal movement in vise.

Head rise before completed cut.

|

Tooth Fracture

|

Material loose in vise.

Guides not adjusted properly.

Incorrect tooth pitch.

Approach to work too fast.

Excessive feed pressure or band speed.

|

Chip Welding

|

Improper coolant or mix.

Excessive feed pressure or band speed.

Improperly adjusted or worn chip brush.

|

Teeth Stripping

|

Material not securely vised.

Improper or insufficient coolant.

Excessive feed pressure.

Tooth lodged in cut or hard spot in work.

Tooth pitch too coarse for work piece.

|

Band Scoring

|

Check for guide insert wear or breaks.

Excessive pressure on guide inserts.

Check alignment of guide arms.

|

Inaccurate Cut

|

Teeth dull or excessive feed pressure.

Set worn on one side.

Guides worn or loose.

Guide arms too far from work.

Insufficient blade tension.

Chips carried into kerf.

Possible hard inclusion in work.

|

Rough Cut

Surface

|

Dull or damaged blade.

Insufficient blade tension.

Guide inserts loose or worn.

Excessive feed pressure.

Tooth pitch too coarse.

|

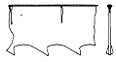

Dished Cut on

Round Stock*

|

Use normal feed rate on first 1/3 cut.

Reduce feed rate on center 1/3 cut.

Increase to normal feed rate on final 1/3 cut.

|